一、summarize

DRPI modular terminal distribution box is suitable for AC 50Hz rated voltage up to 400V, rated power to 125A

Internal power distribution and protection for home, commercial and industrial use.

This product can be installed inside the isolation switch, miniature circuit breakers, leakage circuit breakers, fuses, modular sockets, surge protectors, etc. TH3576 tracking installation of terminal electrical components.

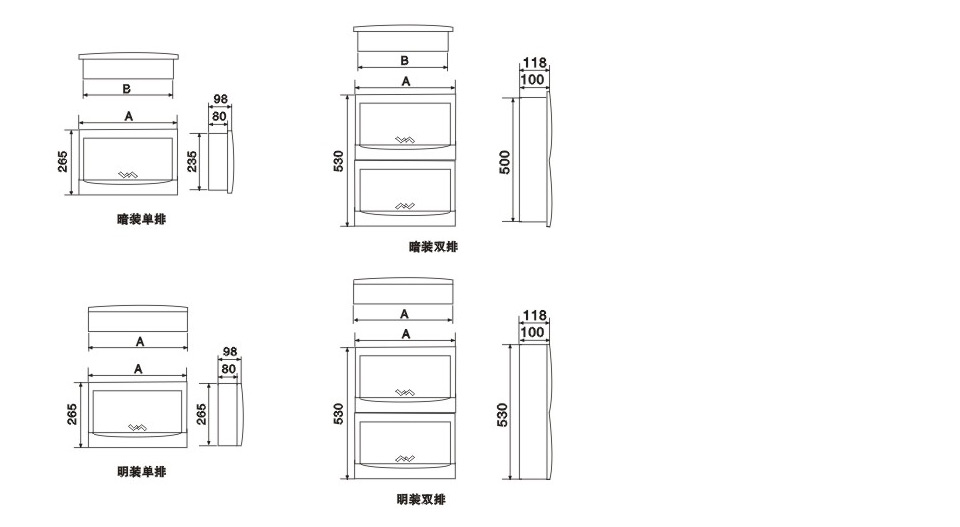

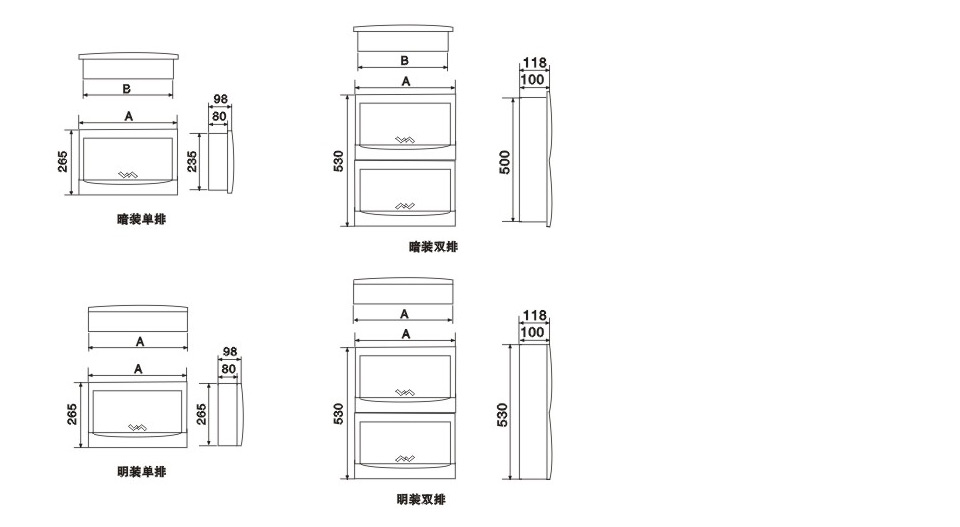

The product is installed in two types, concealed and mounted. The total unit modulus of the installable electrical components (a module per 18mrn) is 6, 12, 16, 20, 24, 32, of which 24, 32 two kinds adopt double row structure.

DRPI modular terminal distribution box meets the criteria of lEC60439-3`GB7251,3 and has achieved mandatory productionProduct Certification (CCC) certificate.

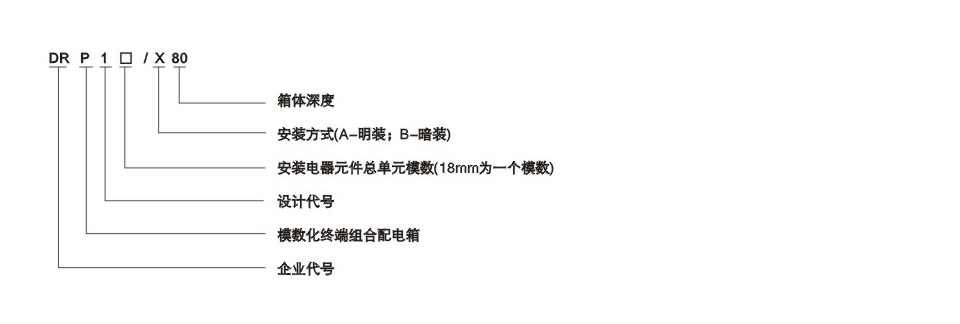

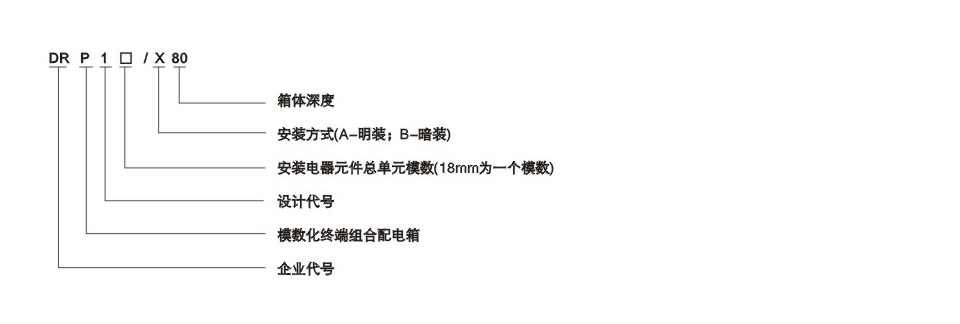

二、product model and meaning

三、 main performance and technical parameters

三、 main performance and technical parameters

structure

1. The box body is made of cold-rolled steel plate and welded and spray-molded. The machine has high strength and beautiful appearance.

2. The cover is made of white flame retardant anti-UV ABS plastic. High strength • No discoloration • High safety • Beautiful appearance.

3, movement can be easily removed from the box, the construction of the box can be embedded, greatly facilitate the construction.

4, the surface cover is fixed on the movement structure, and the movement can be kept horizontal, so even if the box is tilted

Still can keep the appearance straight.

Protection class, pollution class, electric shock protection and overvoltage category

1. The protection level is lP41, which can prevent foreign matter from entering and touching live conductors. It can also prevent liquid from dropping vertically.

2, the pollution level is 2 and 3 levels. Can be used at home and similar occasions, can also be used for general industrial sites.

3, electric shock protection: The protection of direct contact can be completed according to the structure of the product itself. (For example, the insulation of electrified parts shall be selected as stalls and the partitions shall isolate the live parts.) The protection of electricity can be accomplished by means of installation and protection measures.

Protective appliances may consist of separate protective conductors or bare conductive parts. Structurally, measures are taken to ensure the continuity between the bare conductive parts of the product and between these parts and the protection circuit.

4. The overvoltage categories are Il and lll, which can tolerate 4KV impulse voltage.

Electrical performance

DRP1 modular terminal distribution box meets GB7251.3 standard, its temperature rise, dielectric properties, clearances and creepage distance, short circuit protection functions are in line with GB7251.3 standard.

Main circuit connection

1. In the standard configuration, the copper bar is used to connect the main switch and the branch switch, and is connected to each branch switch by the branch copper bar.

2. When the electrical components are configured according to the electrical drawings required by the customer, the main switch and the branch row (bus bar) are connected by a stranded wire and a cold-pressed joint, and the branch copper row is connected to the branch switches. The cross section connecting the hunting lines is in accordance with GB7251.3 regulations.

四、configuration instructions and structural features

|

material

|

|

Face ABS resin

|

|

Bottom box

|

Concealed SPCCt 1.0

|

|

Surface mounted SPCCt 1.2

|

|

colour

|

milky

|

|

Protection level

|

lP41

|

|

Distribution System

|

Single-phase second-line + ground three-phase four-wire + ground

|

五、appearance of specifications

|

Type

|

Mounting element modulus

|

A

|

B

|

Note

|

|

DRP1-08

|

8

|

258

|

228

|

single row

|

|

|

12

|

330

|

300

|

single row

|

|

|

DRP1-12

|

16

|

402

|

372

|

single row

|

Single row with80mm

|

|

DRP1-16

|

20

|

474

|

444

|

single row

|

Double row100mm

|

|

DRP1-20

|

24

|

330

|

300

|

single row

|

prior choice

|

|

DRP1-24

|

32

|

402

|

372

|

Double row

|

|

|

DRP1-32

|

40

|

474

|

444

|

Double row

|

|

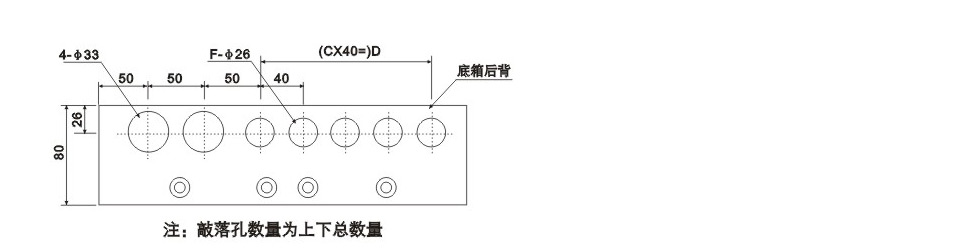

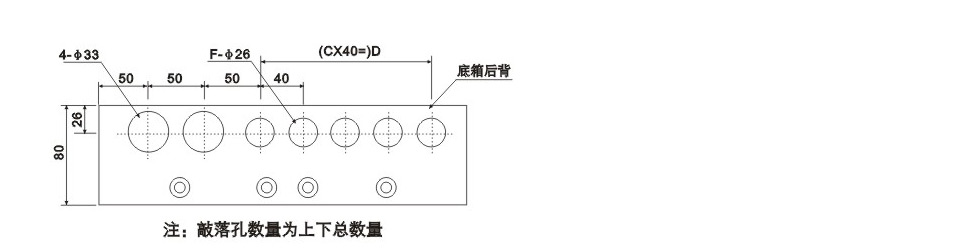

六、standard knock hole size

|

Type

|

F

|

C

|

D

|

|

DRP1-08

|

4

|

1

|

40

|

|

8

|

3

|

120

|

|

DRP1-12

|

10

|

4

|

160

|

|

DRP1-16

|

14

|

6

|

240

|

|

DRP1-20

|

8

|

3

|

120

|

|

DRP1-24

|

10

|

4

|

160

|

|

DRP1-32

|

14

|

6

|

240

|

Note: The number of knockout holes is the total number of up and down

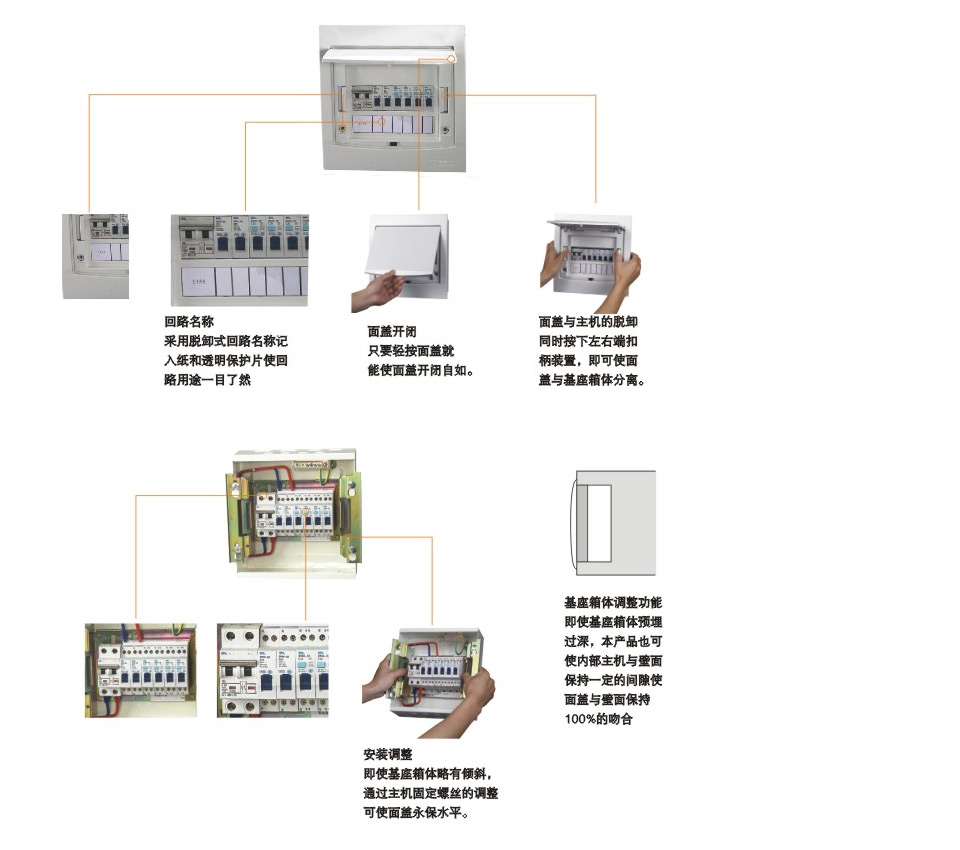

七、 structure

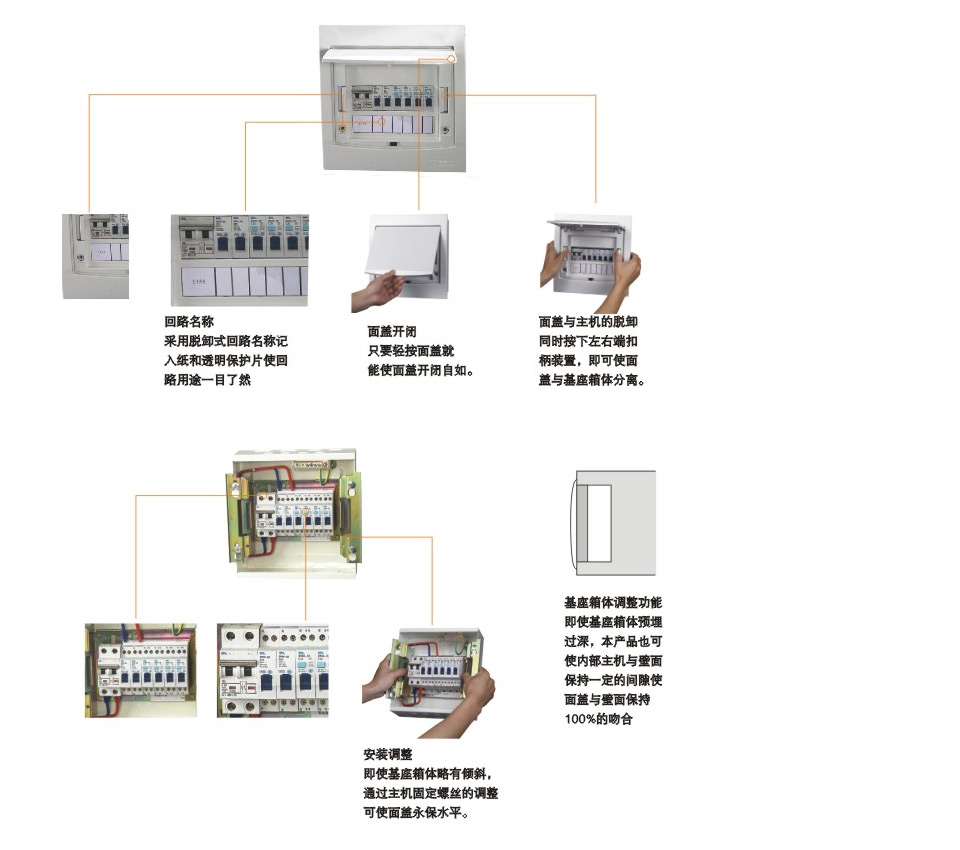

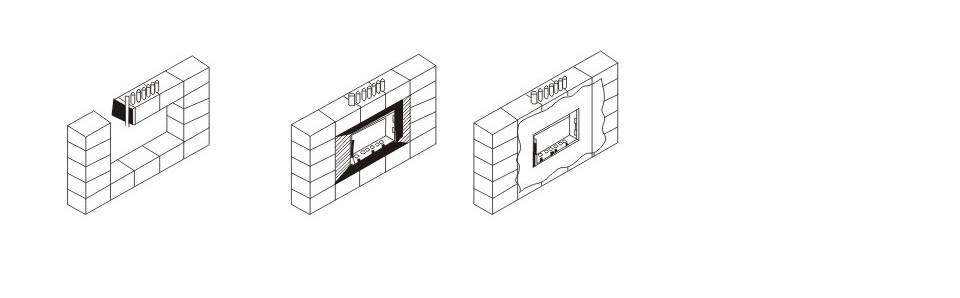

八、shape structure and installation

Each attachment name

Prepare before assembly

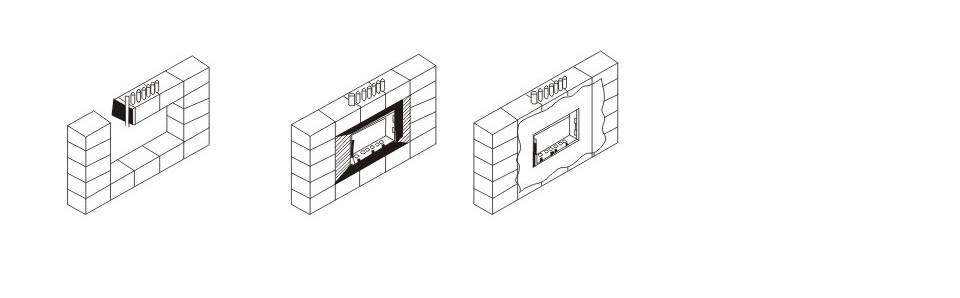

Box installation

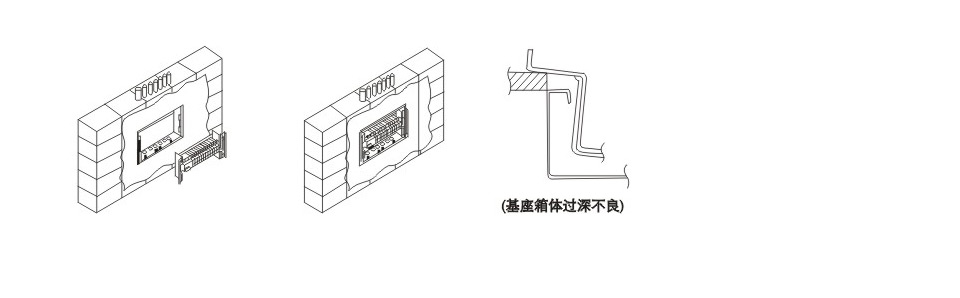

1. Put the base box body and connect the wire tube in the pre-embedded hole slightly larger than the base box.

2. Repair gaps and walls around the base box.

3. Note: After the last correction of the wall, the base box part must not be raised above the wall • It should be kept on the same level as the wall surface.

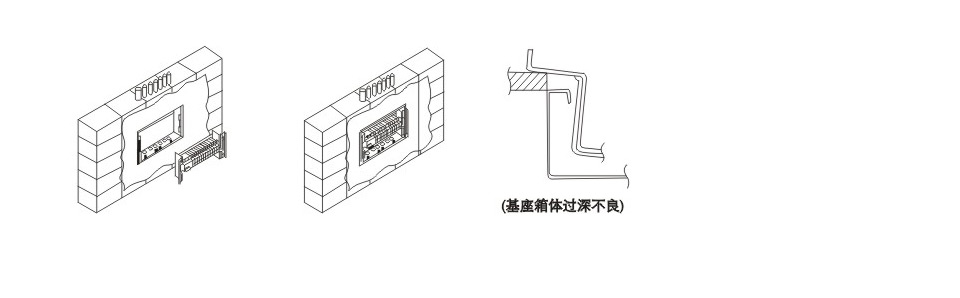

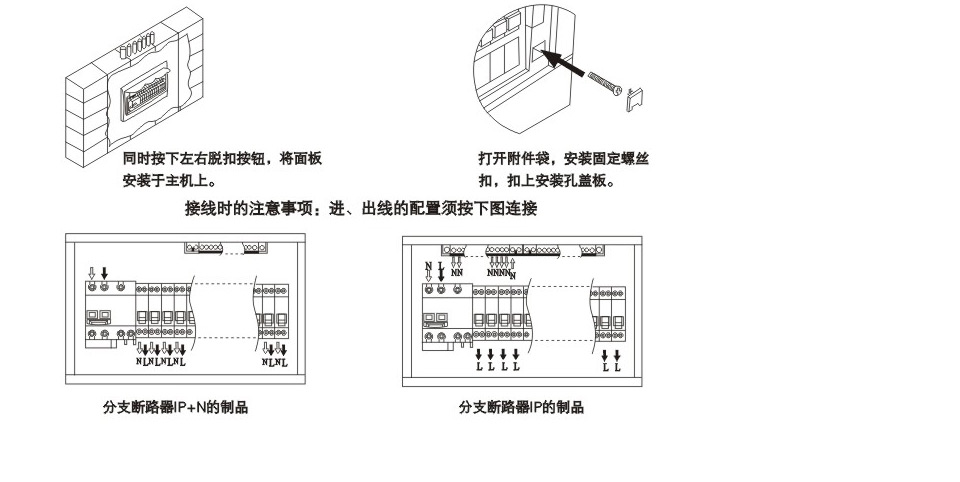

Host installation

1. Fix the main unit with fixing screws.

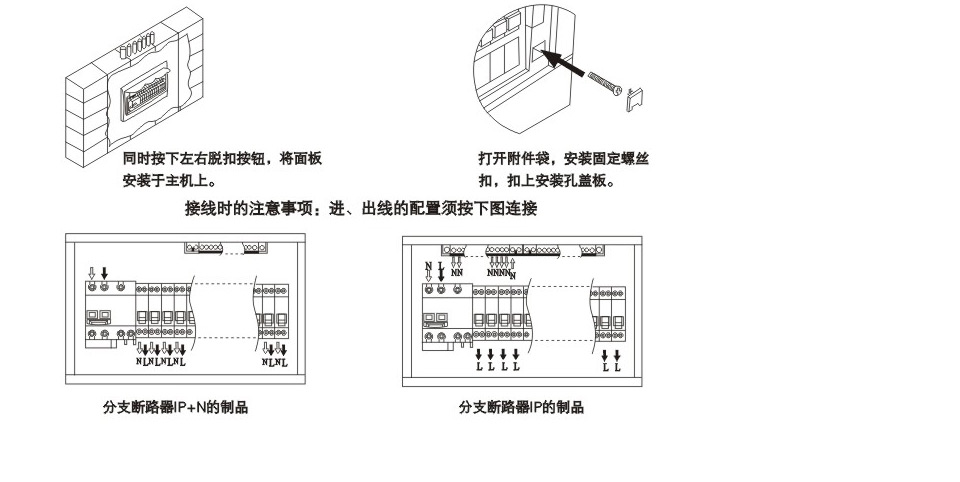

2, connect into the line and outlet

(Note: The main circuit breakers and branch circuit breakers have been connected by copper bars, users do not have to operate)

3` When the main unit tilts, loosen the fixing screw to adjust the main unit to water

Flat position, then tighten the fixing screws.

Cover installation

九、ordering instructions

1, the customer provides a detailed system; 2, the installer installed or concealed); 3, the depth of the bottom box: if not marked then

According to Delong standard size; single row depth: 60mm double row depth: 101m

Non-standard products 1. No knock-out hole requirements 2. Customer knock-out hole size 3. Connection method

4, other special requirements.